CobraFlex DTF Tranfers: A Comprehensive Guide

Chapter 1: The Science Behind Heat Pressing

Before diving into exact settings, it's important to understand the science of heat pressing. When a DTF transfer is applied using heat and pressure, the adhesive layer on the back of the film melts and bonds to the fibers of the garment. For this bond to be durable and visually appealing, three key elements must be dialed in:

- Temperature – too hot and you may scorch fabric or distort the transfer; too cold and the adhesive won’t melt properly.

- Time – pressing too long can cause the ink to overbake; too short and the adhesive won’t fully set.

- Pressure – adequate pressure ensures the adhesive embeds properly into the garment fibers.

CobraFlex DTF transfers are engineered to work under high-speed conditions with low dwell time, making them incredibly efficient—as little as 1–3 seconds per press.

Chapter 2: CobraFlex DTF Transfer Settings (Manufacturer Specifications)

Let’s break down the official CobraFlex specifications for pressing garments:

1. Polyester

- Temperature: 285°F

- Time: 1 to 2 seconds

- Pressure: Firm (100–150 PSI recommended)

- Peel Type: Hot Peel

This quick-press setting is ideal for athletic wear, jerseys, and performance apparel. Polyester is heat-sensitive, so the ultra-short press time helps prevent scorch marks, shine, or dye migration.

Pro Tip: For optimal results on dark polyester, consider using a parchment cover sheet after peeling for a quick 2-second post-press to seal in color vibrancy.

2. Cotton

- Pre-Press: 2 seconds to remove moisture

- Temperature: 285°F–290°F

- Time: 3 seconds

- Pressure: Firm

- Peel Type: Hot Peel

Cotton holds moisture and requires a pre-press to drive it out. This improves adhesion and minimizes bubbling or lifting. The slightly longer 3-second press gives the ink and adhesive time to fully bond to the garment fibers.

In Humid Conditions:

Increase press time from 3 to 4 seconds if moisture is still present after pre-pressing.

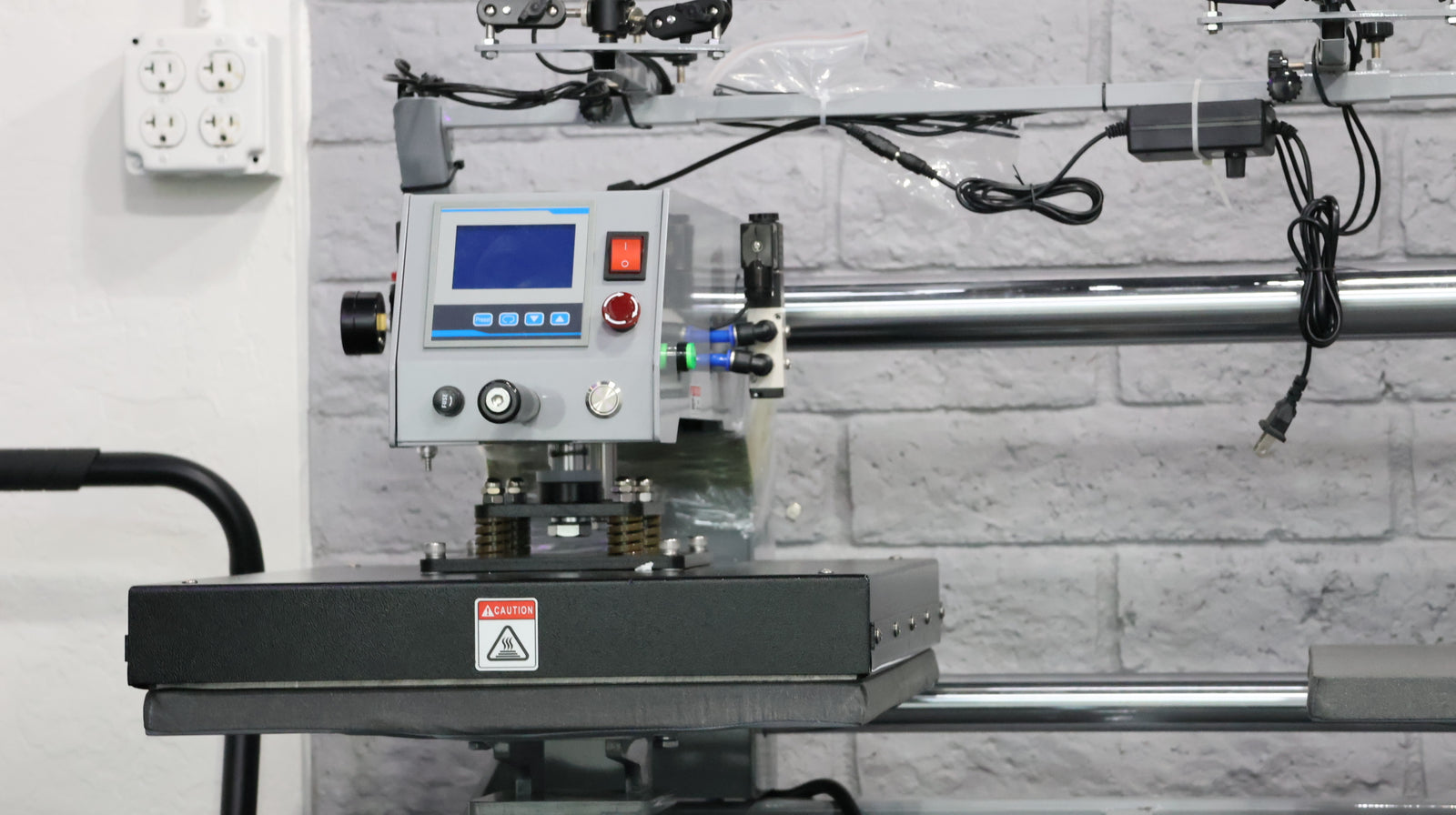

Chapter 3: How to Use Your Heat Press with CobraFlex Transfers

Step-by-Step Workflow:

Set Your Heat Press

- Set the temperature according to your fabric type.

- Adjust pressure to firm—check using the dollar-bill or pressure strip test if you're unsure.

Garment Prep

- Place the garment on the press platen, smooth out wrinkles.

- Pre-press cotton or any moisture-retaining fabric for 2 seconds.

Align Your Transfer

- Place the CobraFlex DTF transfer film ink-side down on the garment.

- Use a T-square or laser guide for consistent placement if needed.

Press It

- Press for the specified time:

- 1–2 seconds for polyester

- 3 seconds for cotton or in humid environments

- Maintain even, firm pressure.

Peel While Hot

- Immediately peel the film at a 45° angle—do not wait for it to cool.

Optional Post Press

- For added durability or a matte finish, place a cotton sheet over the design and press for another 2 seconds.

Chapter 3.5: Heat Gun vs. Heat Probe – Why Accuracy Matters

When it comes to heat pressing, ensuring your press reaches and maintains the correct temperature is crucial. Relying solely on your heat press's digital display can be misleading, as actual platen temperatures may vary due to factors like uneven heating or sensor inaccuracies. To guarantee optimal results, it's essential to independently verify the platen temperature.

The Limitations of Handheld Infrared (IR) Thermometers

Handheld IR thermometers, commonly known as heat guns, are popular for their convenience and non-contact measurement capabilities. However, they have notable limitations:

- Surface Dependency: IR thermometers measure surface temperatures based on emitted infrared radiation. Reflective or shiny surfaces, like aluminum platens, can lead to inaccurate readings due to their low emissivity.

- Emissivity Variations: Different materials emit infrared radiation differently. Unless your IR thermometer allows for emissivity adjustments, readings can be off by significant margins.

- Distance-to-Spot Ratio: The accuracy of IR thermometers diminishes with distance. If the target area doesn't fill the device's field of view, readings can be influenced by surrounding temperatures.

The Precision of Contact Heat Probes

Contact heat probes, such as thermocouples, provide direct temperature measurements by physically touching the platen surface. Their advantages include:

- High Accuracy: By measuring the actual surface temperature, contact probes offer precise readings, unaffected by surface reflectivity or ambient conditions.

- Detection of Cold Spots: Probes can identify temperature inconsistencies across the platen, ensuring uniform heat distribution.

- Calibration Reference: They serve as reliable tools for calibrating your heat press, ensuring that digital displays align with actual temperatures.

For example, the Digital Heat Press Temperature Probe from Colman and Company utilizes a K-Type thermocouple to deliver accurate surface temperature readings, making it an invaluable tool for heat press calibration.

Chapter 4: Troubleshooting Common Issues

Disclaimer: Every heat press, workspace, and environment is different. Variables such as humidity, garment thickness, platen accuracy, and press age can all affect results. While the settings in this guide are based on CobraFlex manufacturer recommendations, it is essential to test settings on your own equipment and adjust as needed for optimal results.

Issue: Transfer Not Sticking

- Possible Cause: Too low pressure or temperature, or skipped pre-press.

- Solution: Repress for 2–3 more seconds with firm pressure and ensure proper pre-pressing for moisture removal.

Issue: Edges Lifting After Washing

- Possible Cause: Improper pressure or early peel.

- Solution: Always peel hot (unless using thick garments—see next tip), and apply firm, even pressure.

Issue: Ghosting or Shadowing

- Possible Cause: Garment shifted after pressing or peeling too slowly.

- Solution: Hold the garment steady while peeling; consider heat-resistant tape for alignment.

Issue: Thicker Garments Holding Excess Heat

- Possible Cause: Heavy garments (like hoodies or fleece) retain heat longer than thinner fabrics, making hot peel difficult.

- Solution: Allow the garment to cool slightly, then try a cold peel instead of a hot peel. If the film resists peeling or causes distortion, wait another few seconds and peel at a slower, controlled pace.

General Tip:

- Always test press a sample from the same batch of garments before running full production.